Alumina ceramic plates in the energy sector

Alumina ceramic substrates embody a unique blend of durability, versatility, and functionality, making them an attractive choice for a diverse range of applications. Whether it's the rigorous demands of industrial operations or the intricate requirements of medical technologies, these tiles consistently deliver exceptional performance.

In industrial settings, alumina ceramic tiles are a staple due to their remarkable ability to withstand high temperatures, corrosion, and wear. This resilience enables them to excel in environments that involve abrasive materials, harsh chemicals, or extreme heat, ensuring reliability and longevity.

Moreover, alumina ceramic tiles have found a niche in the medical field, where their biocompatibility and exceptional hardness make them ideal for use in implants and prosthetic devices. Their strength and durability contribute to the development of reliable and long-lasting solutions that patients can trust.

Additionally, the electronics industry also relies heavily on alumina ceramic tiles due to their superior electrical insulation and thermal conductivity properties. These properties are crucial for ensuring the safe and efficient operation of electronic devices, making alumina ceramic tiles an indispensable component in the manufacturing process.

With their exceptional versatility, longevity, and resistance to various environmental factors, alumina ceramic tiles have become a valuable asset in numerous industries, underlining their significance in a wide range of applications.

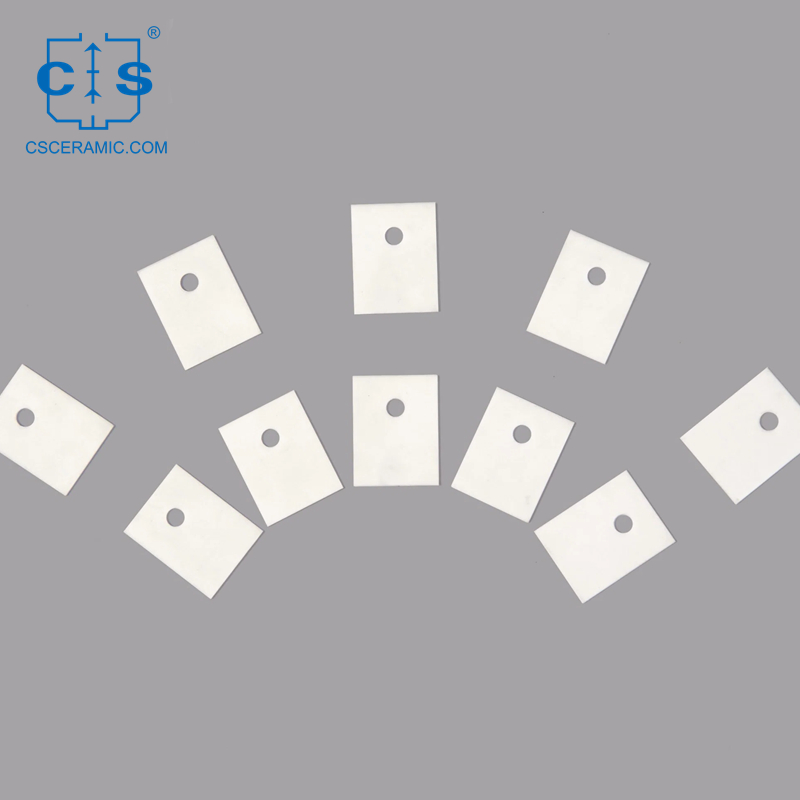

Characteristics of alumina ceramic Substrates

Alumina ceramic substrates stand as a remarkable engineering solution, esteemed for their unique fusion of properties that cater seamlessly to a multitude of applications. At the heart of these substrates lies aluminum oxide, a ceramic material acclaimed for its unparalleled hardness, strength, and remarkable thermal stability. A defining feature of alumina ceramic substrates is their Mohs hardness rating of 9, which positions them among the hardest materials, second only to diamond, offering exceptional resistance to scratches, abrasion, and wear. This exceptional hardness underpins their durability, ensuring resilience in harsh industrial and medical environments. Moreover, their exceptional thermal properties, which encompass both efficient heat transfer and remarkable insulation capabilities, make them an ideal choice for applications involving high temperatures, such as industrial furnaces, gas turbines, and precision electronics.

Benefits of using alumina ceramic Substrates

Alumina ceramic substrates are a highly desirable material in numerous industries, thanks to their exceptional properties that offer a myriad of benefits. Their remarkable durability and longevity, stemming from their unparalleled hardness, strength, and resistance to wear, corrosion, and thermal stress, are among their primary advantages. Moreover, their versatility is noteworthy, as they can be tailored to fit the specific needs of various applications, including those in automotive, aerospace, medical, and electronics. Their resilience to harsh temperatures, corrosive conditions, and mechanical loads makes them an ideal candidate for demanding applications. Their exceptional thermal properties—effective heat transfer coupled with insulation capabilities—are crucial in thermal management, essential in electronics and high-performance engines. While they may initially carry a higher cost compared to some materials, their long-term cost-effectiveness, driven by their durability and reduced maintenance requirements, makes them a financially prudent investment for industries with rigorous operational standards.

Alumina ceramic substrates in the energy sector

The energy sector, with its increasing focus on efficiency, sustainability, and reliability, has become another significant beneficiary of the exceptional properties of alumina ceramic substrates. These substrates are finding a wide range of applications in the generation, transmission, and storage of energy, contributing to the advancement of various energy technologies.

One of the key applications of alumina ceramic substrates in the energy sector is in the design and construction of power generation equipment, such as turbines and generators. The high thermal conductivity and resistance to wear and corrosion of these substrates make them ideal for use in components that are exposed to extreme temperatures, pressures, and harsh operating conditions. Alumina ceramic substrates are commonly used in the construction of combustion chambers, blades, and other critical parts of power generation systems, ensuring their reliable and efficient operation.

In the field of renewable energy, alumina ceramic substrates are playing a crucial role in the development of advanced solar photovoltaic (PV) cells and modules. The excellent electrical insulation properties of these substrates make them an essential component in the design of PV cells, where they help to protect the delicate semiconductor materials from electrical shorts and other failures. Additionally, the thermal management capabilities of alumina ceramic substrates are crucial in maintaining the optimal performance of solar PV systems, particularly in high-temperature environments.

The energy storage sector has also recognized the benefits of alumina ceramic substrates. These substrates are finding applications in the design and construction of high-performance batteries and fuel cells, where their exceptional electrical insulation and thermal management properties are critical. Alumina ceramic substrates can be used as separators, insulators, and structural components in these energy storage systems, helping to improve their safety, efficiency, and overall reliability.

Beyond their use in power generation and energy storage, alumina ceramic substrates are also playing a role in the transmission and distribution of energy. These substrates are used in the fabrication of high-voltage electrical insulators, which are essential for the safe and reliable operation of power grids and electrical infrastructure. The exceptional dielectric strength and thermal stability of alumina ceramic substrates make them an ideal choice for these critical applications.

As the global demand for clean, efficient, and reliable energy continues to grow, the versatility and performance of alumina ceramic substrates will become increasingly important in driving innovation and progress in the energy sector. The exceptional properties of these substrates will continue to be leveraged in the development of next-generation energy technologies, further cementing their importance in the quest for a sustainable energy future.

Conclusion

Evident from this discourse, alumina ceramic substrates stand as a paramount resource in the realm of energy sector, owing to their unparalleled versatility and enduring longevity. Their distinctive characteristics, such as unparalleled hardness, steadfast thermal resilience, impeccable electrical insulation, and robust chemical inertness, have firmly established them as a cornerstone in myriad pivotal applications.

Anticipating the future trajectory, it is undeniable that the appetite for alumina ceramic substrates will soar as industries endeavor to innovate towards greater efficiency, dependability, and environmental harmony. The substrates' prowess in enduring the harshest of environments and functioning seamlessly under extreme conditions will only amplify in significance as technological advancements propel the demand for superlative materials to new heights.

评论

发表评论